News

How We Made A Fundamentally Better Transmission for Next Generation EVs

Electric vehicle adoption is accelerating at a record pace – nearly 14 million EVs were sold in 2023 (about 18% of all new cars). As the industry scales, automakers face intense pressure to improve range and performance while driving costs down. One often-overlooked opportunity is the transmission: most EVs use a simple single-speed gearbox today, but this “one-size-fits-all” approach forces compromises between acceleration, top speed, and efficiency. Ingear addresses three major gaps in legacy ICE-Age multispeed transmissions…

Two Gears Beat One in EVs—And How Ingear Made It Finally Practical

The Need for Smarter EV Transmissions

Electric vehicle adoption is accelerating at a record pace – nearly 14 million EVs were sold in 2023 (about 18% of all new cars). As the industry scales, automakers face intense pressure to improve range and performance while driving costs down. One often-overlooked opportunity is the transmission: most EVs use a simple single-speed gearbox today, but this “one-size-fits-all” approach forces compromises between acceleration, top speed, and efficiency. Ingear addresses three major gaps in legacy ICE-Age multispeed transmissions by being:

(1) Low cost – it uses proven mechanical technology and common materials rather than expensive exotic components.

(2) High efficiency – its innovative design minimizes energy losses so more battery power translates to vehicle motion and extended range.

(3) Smooth shifting – it shifts gears seamlessly without jolts or pauses in power, preserving the effortless driving feel EV owners expect, while reducing wear on the motor and drivetrain.

We dive deeper on why ICE-age transmission options (traditional multi-speed automatics, dual-clutch gearboxes, CVTs, or the status-quo single-speed) fall short on one or more of these criteria for EVs in our article in “How Transmissions Became A Part Of Every Car, And Why They Will Again In The EV Era”.

In short, Ingear was conceived as the inevitable next step – a transmission designed from the ground up to meet all three needs at once. The result is a patented two-speed system that delivers the efficiency gains of a multi-speed gearbox without the cost, weight, or roughness penalties, making it a game-changer for the EV market.

How Ingear Works: The Engineering Behind the Innovation

A. The Core Transmission Concept

Ingear’s core concept is a purpose-built multi-speed transmission for EVs rather than a repurposed ICE vehicle gearbox. Most EV powertrains today use a fixed reduction gear train (typically totalling around 9:1 ratio) between the motor and wheels. Ingear introduces a second, lower gear ratio for improved launch acceleration and hill climbing, and a higher gear for efficient cruising – but it achieves this with elegant simplicity. Instead of adding bulky gearsets or clutches, Ingear replaces one of the fixed gear stages with a continuous silent chain drive and an innovative morphing sprocket. In essence, the transmission uses a strong chain running over two sprockets (one at the motor output and one at the differential input) to transmit power. By “morphing” the diameter of the output sprocket, the system can switch between a low gear (larger sprocket radius) and high gear (smaller sprocket radius) on the fly. This entire shift mechanism is built in without requiring a traditional clutch or complex multiple gear trains.

Crucially, the Ingear design keeps the architecture lean to avoid the weight and efficiency drawbacks that plagued earlier multi-speed EV attempts. There is no torque converter, no multi-plate clutch pack, no synchros and no high-pressure hydraulic circuit needed to actuate shifts. Instead, a simple solenoid actuator slides the sprocket segments (more on that below) at the precise moment when load on that segment is zero, while the motor controller momentarily adjusts speed to synchronize the shift. Because of this clever timing, shifts complete in under one wheel revolution – in some designs as quick as 19 milliseconds – with virtually no perceptible change in drive torque. The motor never fully “uncouples” from the wheels during a gear change, so the car continues to be pushed smoothly forward even as the ratio changes. This is enabled by what we call our “continuous torque” geometry, meaning the motor’s torque flow to the wheels is never interrupted, even in mid-shift. In practice, the driving experience feels like a single-speed EV – smooth and seamless – except the vehicle gets to leverage a second gear for better performance and efficiency. By designing this system specifically for EV requirements, Ingear maximizes efficiency (only a single gear mesh and a chain are in the power path, with no parasitic drag from idling gears or clutches) and keeps the solution compact. It essentially adds a second gear without adding a full ICE-age gearbox. The result is a transmission that delivers the best of both worlds: multi-speed performance gains with nearly the simplicity, efficiency, and cost of a single-speed drive.

B. Segmented Gear Design

At the heart of Ingear’s innovation is its morphing output sprocket – a segmented gear that can change its effective diameter during a shift. Rather than two separate fixed gears for high and low, Ingear uses one gear built from multiple interlocking segments that slide one at a time to alter the gear ratio. In high-gear mode, these segments retract inward, forming a smaller-radius sprocket. In low-gear mode, the segments extend outward to create a larger-radius sprocket that slows the output relative to the motor for increased torque. During a shift, an actuator pushes a track out to slide one “free” segment at a time into the chain’s path, “assembling” the larger sprocket step by step. Thanks to careful geometry, the chain stays engaged on the smaller-radius portion until the new segment is almost fully in place, so torque continues flowing through the already-engaged part of the sprocket. As the vehicle’s output shaft rotates, five segments move to form the new gear before the shift completes. When downshifting (high to low gear), the first segment to move has a special curved lead-in that smoothly lifts the chain onto the expanding sprocket without any jerk or binding. Likewise, when upshifting, the last segment to retract has a guide that eases the chain back down to the smaller radius. This ingenious segmented approach means the chain never has to derail or jump between sprockets; it always runs in-plane, and the effective gear ratio changes within one rotation of the wheel.

This segmented design enables smooth, reliable shifting with minimal mechanical complexity. It avoids the clutches, synchromesh, or heavy gearing found in traditional transmissions, making it well-suited for efficient mass production using standard materials and processes. The result is a durable, low-cost system that delivers multi-speed benefits without sacrificing simplicity.

C. 3-Post Chain Configuration

Ingear’s power transfer uses a 3-post chain drive configuration: the chain wraps around three sprockets forming a triangle – the drive sprocket from the motor, the driven (morphing) sprocket at the output, and a third sprocket that functions as an idler/tensioner. This design was inspired by the efficiency of chain drives (like those in motorcycles or timing drives) but avoids the lateral chain shifting of a bicycle derailleur system. By keeping the chain on a single plane, Ingear can use a robust automotive chain (a BorgWarner HY-VO type, similar to those used in 4x4 transfer cases) which is proven to handle high torques reliably. Chain drives are actually highly efficient – the Ingear prototype’s chain is slightly more efficient than the helical gear it replaces in a traditional EV reducer. In fact, overall bench testing by a major OEM showed the Ingear transmission reaching over 99% peak efficiency , a level of minimal loss that essentially bests a single-speed gearbox. This is partly because a well-designed chain drive has very low friction – modern roller chains under proper lubrication can exceed 98% efficiency in power transfer – and partly because Ingear eliminates one of the meshing gear stages that a single-speed would otherwise use. There are no parasitic losses from multiple gear meshes being engaged at once, as can happen in multi-speed planetary transmissions, and no sliding friction “rolling” losses between gear teeth. The chain engagement is positive and rolling, with negligible slip.

The 3-post layout improves load distribution and durability. The chain wraps around a large portion of each sprocket, spreading the force over many teeth, unlike a gear mesh where typically only a couple teeth share the load at any instant. The additional contact and wrap angle provided by the tensioner sprocket means smoother force transfer and less stress per link in the chain. Furthermore, using straight-cut sprocket teeth (as opposed to helical gears) means the forces stay in the plane of the chain without generating axial (sideways) thrust. This allows the use of low-friction ball bearings instead of bulky thrust bearings , and it also avoids the efficiency loss and heat generated by sideways forces and gear sliding. In fact, because Ingear’s chain and sprockets do not create significant side loads or friction, the unit requires no dedicated oil pump for lubrication or cooling – simple splash lubrication is sufficient. This contrasts with conventional multi-speed automatics or even some single-speed reducers that need oil pumps and coolers to manage heat. By simplifying the cooling and lubrication, Ingear saves energy (no pump draw) and weight, further contributing to vehicle efficiency.

From a reliability standpoint, chain drives have come a long way – they are widely used in engines and drivelines with long life. Ingear’s chain operates in a sealed environment and stays within normal tension limits, so it doesn’t suffer from stretch or excessive wear. As noted, extensive durability testing showed no measurable chain wear after an accelerated lifetime of use. Noise is also well-controlled; straight-cut gears and chain might sound old-fashioned, but in practice a properly tensioned chain drive can run very quietly. (For instance, the Chevrolet Volt employed a chain in part of its drive system, and it remained inaudible in electric mode.) Ingear leverages these advantages: an efficient, cost-effective, and compact chain drive that replaces a bulky second gearset. By using common materials (hardened steel links and sprockets) and established manufacturing processes (the chain is off-the-shelf from a Tier-1 supplier, and the sprockets can be made with standard methods), the Ingear is truly OEM-friendly. Automakers can integrate this 2-speed unit around the existing differential with minimal re-engineering – it’s designed to fit where a single-speed reducer would fit , only adding a modest amount of mass. In return, they get a significant boost in performance and efficiency.

D. Integrated Tensioning System

A key enabler of Ingear’s smooth operation is its integrated tensioning system. The third “post” in the 3-post design is not just an idler but an active tensioner that automatically maintains the correct chain tension through all operating conditions. In the cutaway image above, this is the spring-loaded arm pushing on the chain loop. The tensioner takes up slack when the sprocket segments retract (upshift) and lets out a bit of slack when the sprocket expands (downshift), so the chain is never overly loose or tight. This prevents any lag or snatch in torque transfer during a shift – there’s no whiplash in the chain and no need for a motor torque pause to wait for engagement. By optimizing force distribution, the tensioner ensures each link and tooth carries just the right load, which prevents power loss due to slippage and eliminates excessive strain on components.

Ingear’s tensioning system is designed to react instantaneously and in concert with the shift. When an upshift or downshift occurs, the control software momentarily modulates motor torque (using a torque-fill algorithm) to make the shift ultra-smooth, while the mechanical tensioner keeps the chain perfectly taut. The result is that passengers cannot even tell a shift is happening – tests indicate shifts are imperceptible in normal driving. Even during regenerative braking, which effectively puts force through the drivetrain in reverse, the tensioner manages the chain slack so that regen can continue uninterrupted through a gear change. Many simpler two-speed setups would have to temporarily suspend regeneration or use clutches to shift, but Ingear’s system keeps regeneration continuous, including during downshifts, again thanks to the coordinated tensioner and motor control. This is a unique advantage in real-world driving: whether accelerating or decelerating, the vehicle behaves seamlessly as if it were single-speed, with the extra gear ratio only making itself known by improving efficiency and performance.

By maintaining proper chain tension and eliminating shock loads, the tensioner reduces wear and enhances durability. Fully sealed and designed to last the vehicle’s lifetime, it requires no periodic adjustment. This blend of simple mechanical design and smart software coordination exemplifies Ingear’s approach: achieving multi-speed performance with minimal complexity.

Bringing it all together:

The result is a transmission that extends range, sharpens performance, and reduces system stress—without introducing new trade-offs. Ingear maintains over 99% peak mechanical efficiency, enabling OEMs to either shrink battery size or deliver longer range at no added cost. Less heat, less waste, and smoother torque delivery make it easier to meet efficiency targets and simplify thermal management. For platforms under pressure to compete on both performance and price, Ingear unlocks meaningful gains using existing components and familiar architectures.

The Next Generation of EV Transmissions Is Already Here

The transmission problem in EVs has been solved—and it’s no longer theoretical. Ingear is already undergoing validation with major OEMs, showing measurable improvements in drivability, range, and system efficiency. It’s built from standard components, designed for mass production, and proven to work in real-world conditions. Independent testing confirms it’s the most efficient 2-speed EV transmission available today.

Unlike legacy gearbox concepts adapted from internal combustion, Ingear was built from the ground up for electric powertrains. The result: smoother torque delivery, over 99% peak mechanical efficiency, and a design that integrates cleanly into existing vehicle architectures. No rare-earth materials. No exotic manufacturing. No need for clutches, pumps, or complex controls. Just a compact, validated drivetrain upgrade that enables platform-wide cost and performance gains.

The window is open for OEMs to gain a fast follower advantage. Those who act now can unlock vehicle-level savings and performance improvements their competitors are still chasing—and send a clear signal to markets and customers that they’re building EVs for what comes next.

About Inmotive Inc.

Inmotive is a pioneering developer of ultra-efficient multi-speed powertrains for electric vehicles. The company’s flagship product, the Ingear™ transmission, delivers superior efficiency and performance for a wide range of EV applications. Committed to advancing sustainable mobility, Inmotive partners with leading manufacturers to redefine what’s possible in electric and alternative energy transportation.

Inmotive Signs Letter of Intent for Multi-Sector Collaboration on Next-Generation Transmission Solutions

Strategic Industry Collaboration will Accelerate the Future of Multi-Speed EV Transmissions

Strategic Industry Collaboration will Accelerate the Future of Multi-Speed EV Transmissions

Toronto, Canada – Jan 8th, 2025 - Inmotive, a leader in ultra-efficient multi-speed transmission technology, has signed a Letter of Intent (LOI) with a top-tier transmission supplier, marking a pivotal step toward bringing next-generation drivetrain solutions to market.

This strategic agreement validates industry interest in Inmotive’s breakthrough Ingear EV 2-speed transmission module and initiates a structured collaboration to advance design for manufacturability, prototype development, and commercial feasibility across multiple vehicle sectors, including off-road, utility, and passenger applications. By working with a Tier-1 supplier with extensive experience in mass production, Inmotive is well-positioned to accelerate the adoption of its technology.

"This agreement underscores the increasing demand for high-efficiency multi-speed electric drivetrains," said Paul Bottero, CEO of Inmotive. "Working alongside an established industry partner allows us to accelerate the commercialization of our technology and drive significant performance and cost benefits for automakers and fleet operators alike."

Under the LOI, both companies will engage in design for manufacturability (DFM), prototype development & testing, customer engagement, and licensing discussions. As the collaboration progresses, both parties will evaluate market viability through a combination of technical assessments, cost modeling, and strategic customer discussions. The agreement lays the groundwork for a potential licensing deal, aligning with Inmotive’s vision to revolutionize vehicle efficiency and electrification.

Further updates will be shared as the partnership advances.

About Inmotive Inc.

Inmotive is a pioneering developer of ultra-efficient multi-speed powertrains for electric vehicles. The company’s flagship product, the Ingear™ transmission, delivers superior efficiency and performance for a wide range of EV applications. Committed to advancing sustainable mobility, Inmotive partners with leading manufacturers to redefine what’s possible in electric and alternative energy transportation.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

How Transmissions Became A Part Of Every Car, And Why They Will Again In The EV Era

For decades, transmissions had been an unquestioned part of automotive design—until electric vehicles came along. With their instant torque and simplified drivetrains, EVs seem to operate well without the multispeed transmissions from the Internal Combustion Engine (ICE) age. However, look back at the early days of the automobile and the development of the first transmissions and you’ll see a landscape that mirrors where EVs are today.

Transmissions Shaped the Auto Industry—And Why EV OEMs Need Them.

For decades, transmissions had been an unquestioned part of automotive design—until electric vehicles came along. With their instant torque and simplified drivetrains, EVs seem to operate well without the multispeed transmissions from the Internal Combustion Engine (ICE) age. However, look back at the early days of the automobile and the development of the first transmissions and you’ll see a landscape that mirrors where EVs are today.

History has a way of repeating itself - Just as early cars first relied exclusively on brute-force engine power to achieve performance targets, today’s EVs are facing similar limitations in efficiency and performance by asking more and more from the electric motors. There comes a tipping point where the trade-offs outweigh the advantages, and we are fast approaching it. As the industry demands longer range and more cost-effective electric powertrains, mulit-speed transmissions will re-emerge as a critical piece of the puzzle. To understand why, we have to look back at how they became essential in the first place.

Early Automotive Design Philosophy

The first cars produced in the late 1800s were simplistic and low-powered. Early car builders often pursued performance by increasing engine size and power output. For example, Benz’s Patent-Motorwagen evolved from a 0.75-horsepower (HP) single-cylinder engine in 1885 to a 1.5HP version in 1887 and a 2HP model by 1888—effectively increasing engine capacity to enhance performance. This “bigger engine” approach would yield improvements to vehicle performance and capabilities , but it had limits: engines became heavier, consumed more fuel and were more expensive. As vehicles started to drive faster and carry heavier loads, it became clear that relying solely on engine size was not a sustainable solution for performance & cost.¹

The Emergence of Transmissions

Technical & commercial challenges in early cars highlighted the need for multi-ratio transmissions. Internal combustion engines have a narrow optimal RPM range for efficiency and torque, so a single fixed gear was a compromise – great for either low-speed torque or high-speed cruising, but not both. An engine geared to launch the car at grade might over-rev or waste energy at higher speeds; an engine geared for high speed would struggle to get the car moving. Early automobiles suffered in efficiency on varied terrain (e.g. climbing hills) and often required oversized engines to compensate. These challenges drove inventors to experiment with gearing.

By the 1890s, the first multi-speed transmissions appeared: The first true gearbox with multiple forward speeds was introduced in 1894 as part of the Panhard et Levassor Type A, using manually shifted gears.². This allowed drivers to change gear ratios and keep the engine in a more effective RPM range, greatly improving both performance, driveability and fuel efficiency, a big advance for the vehicle technology of the time. The trade-off was added complexity and cost, initially posing a challenge for automakers. For transmissions to be widely adopted in mass market passenger vehicles, they had to meet market-driven thresholds in three key areas:

Cost – Feasibility for mass production at competitive prices

Efficiency – Better the ratio of energy input to usable output in the drivetrain

Performance – Improved utility and capability.

1. Cost and Manufacturing Feasibility:

In the earliest years, gearboxes were expensive and complex to build. However, mass-production techniques (pioneered by Ford and others) quickly made transmissions cost-effective to manufacture and install. By the 1920s, two-speed transmissions were standard equipment even on affordable cars, indicating that the cost per unit had dropped and consumers demanded the capability. The planetary 2-speed in the Model T (1908) is a classic example of a simple, robust transmission that was cheap enough to include in a mass-market car, proving the cost hurdle could be overcome.

As designs standardized, transmissions actually saved costs – a car with a smaller engine plus a gearbox could meet performance targets more cheaply than a car that tried to use a very large engine with no gearbox. By the post-WWII era, the economies of scale made even 3- or 4-speed automatics affordable options.

2. Efficiency:

A major impetus for adding a multispeed transmission was to maximize fuel economy through having the engine spend time at its optimum state.. Early manual transmissions often employed sliding-gear designs, which required drivers to manually mesh gears. These transmissions were not synchronized, making gear shifts challenging and less efficient. In contrast, modern automatic transmissions have achieved efficiencies ranging from 86% to 94% through the shift

Each additional gear allowed the engine to run closer to its most efficient RPM over a wider range of vehicle speeds.Transmissions also enabled downsizing engines for economy: an efficient small engine with the right gearing can perform like a larger engine but use less fuel. Regulatory pressure, like those on oil and fuel efficiency in the 1970s, accelerates the transition. In this way the gearbox became a key tool for meeting regulatory requirements over the decades.

3. Performance and Drivability Gains:

For transmissions to gain widespread adoption, they had to meet usability thresholds that ensured an uninterrupted and seamless driving experience. Early transmissions often required significant driver effort, with non-synchronized gears leading to difficult shifts, noise, and excessive wear. However, as engineering improvements enabled smoother, synchronized shifts and automatic options, transmissions became effortless to use and highly reliable over long periods. Once these usability hurdles were overcome, consumers quickly embraced the added performance benefits. A more enjoyable driving experience—all without added complexity for the user. As a result, transmissions transitioned from being a mechanical necessity to a fundamental expectation in vehicle design.

The improvements were the result of engineering effort to meet these thresholds, cementing transmissions as a fundamental component of automotive design since the early 1900s.

The History of ICE Transmission Evolution

The Current State of EV Drivetrain: Big Battery, Big Motor, Single Gear

Today, electric vehicles (EVs) currently use single-speed drivetrains – typically just one fixed gear reduction between the electric motor and the wheels - Similar to the direct drives of the early ICE Age. EV designers have thus far opted to achieve the desired performance and range by using larger, more powerful, faster spinning electric motors, and sophisticated electronic control. This approach has been acceptable to the consumer since electric motors have a much wider speed range than gasoline engines. An EV motor generates peak torque from 0 rpm (launch) and sustains useful power across a broad rpm range (cruise). Automakers have found that they can cover both low-end acceleration and high-speed cruising by selecting an appropriate single gear ratio and then using a motor (or multiple motors) potent enough to deliver on both ends. The industry’s design philosophy so far has therefore been to keep the drivetrain mechanically simple (one gear) and rely on the motor’s flexibility and managing the associated motor complexity

But it hasn’t always been this way. In fact, Tesla’s early experience with the original 2008 Tesla is demonstrative of the challenges of using ICE-age transmissions in EVs. The Tesla Roadster attempted to use a legacy 2-speed transmission to meet its ambitious acceleration and top speed targets. However, the conventional ICE-age gearbox could not handle the high torque and failed in testing, forcing Tesla to abandon it. This transmission couldn’t meet the cost, efficiency, or performance thresholds needed for transmissions to be successful in this new generation of vehicle. Electric motors had changed the game.

Tesla’s solution was to drop the transmission entirely and go with a single-speed, compensating by upgrading to a more powerful motor to hit the performance goals.³ This set the tone for many EVs to come. Manufacturers have, so far, been willing to tolerate the complexity, weight and cost increase of a larger motor in exchange for the mechanical simplicity of a single-speed drivetrain. This is due, in part, to the perception that the complexity, weight and cost of today’s modern transmission is not the most effective way to meet the vehicle requirements. The paradigm to today is to iterate on the motor

EVs suffer from the Inherent Limitations of Single-Speed Drives

The one-gear approach works in a price-insensitive EV marketplace, but it isn’t without compromises. Single-speed setups can push the electric motor out of its ideal efficiency zone, just like the internal combustion engines of the past. At high highway speeds, the motor can spin at a high RPM where its efficiency drops off, wasting energy as heat. Likewise, at very low speeds or heavy loads (towing, steep grades), a single gear might force the motor to draw huge currents to produce the needed wheel torque. Using a single fixed gear ratio means EV designers must make a trade-off between acceleration (torque) and top speed and include excess battery capacity to offset the losses.

Automakers try to find an optimal middle ground, and powerful motors help mask the compromise – but the underlying limitation remains. As Mate Rimac (designer of the Rimac Concept One electric hypercar) explained, “in electric cars you normally need to decide between acceleration or top speed when you have a single-speed gearbox”.⁴

Academic and industry research backs up these examples. Multiple studies have investigated two-speed or multi-speed EV transmissions. For instance, a 2015 simulation study by Zhang et al. found that adding a two-speed gearbox to an EV could reduce energy consumption by ~6.6% and increase driving range by ~7% compared to a single-speed drive.⁵ In general, literature suggests a meaningful efficiency gain on the order of 5–10% with addition of a 2-speed transmission, as well as the ability to use a smaller motor for the same performance.

Product Planners: What could you do with 5-10% more range from the same battery pack?

So Why Haven’t We Seen A Proliferation Of Multispeed Transmissions In EVs?

These efficiency improvements translate into extended range or the possibility of using a smaller battery pack for the same range, which in an industry obsessed with squeezing out every extra mile, is significant. Such findings are spurring continued R&D – evidenced by many patents being filed for multi-speed EV transmission designs. In fact, an analysis by GlobalData found over 120 companies, from startups to major automakers, are actively working on two-speed EV transmission innovations, indicating broad interest in this area. Major carmakers like Hyundai, Mercedes-Benz, and Toyota are among the top patent filers, aiming to enhance acceleration and high-speed efficiency with multi-gear systems in their future EVs.⁶

Why have we seen so few of these make it to market? To date, manufacturers have tried to use ICE-age transmission designs and techniques in EVs to reap the benefits of multi gear setups. These efforts have met challenges, because EVs increased the thresholds in each of the 3 areas:

Cost – EVs drivetrains are simpler and lower cost than their ICE counterparts. EV Transmissions must be compact and ready for mass production at ultra low costs

Efficiency – Due to range anxiety and battery charge times, EV drivetrains demand higher efficiency compared to their ICE counterparts - EV Transmissions must be >97% efficient to add value to the vehicle

Performance – EV fixed-ratio drivetrains are smoother and more powerful than their ICE counterparts. To compete in EVs, multi-speed transmissions must deliver imperceptible shifts with no gaps in torque delivery. However, the high torque and extended RPM range of electric motors place new durability demands on gear design. At the same time, the bar for noise, vibration, and harshness (NVH) is even higher, requiring transmission solutions that enhance performance without compromising refinement.

Conventional ICE-age transmission designs have not met the evolving demands of EVs in these areas. They tend to be costlier, less efficient, and struggle to deliver the seamless shifts required for EV applications. However,If history is any guide, the trajectory of EV drivetrains will eventually mirror that of ICE vehicles in embracing multi-speed transmissions that exceed the market thresholds in all 3 of these areas. To achieve this, invention is required.

That’s why Inmotive conceived a 2-speed transmission that’s fundamentally different - the Ingear is the first example of a transmission that meets the EV demands in all 3 of these categories simultaneously. Our patented technology is similar in costs to a fixed gear drive, operates at >99% efficiency, and has an imperceptible shift with continuous power delivery.

The Road Ahead

In an era where EV manufacturers are engaged in aggressive cost competition, the ability for OEMs to meet performance targets at a lower cost will become a defining factor in market differentiation. Just as multi-speed transmissions allowed smaller, more efficient internal combustion engines to outperform larger, fuel-hungry alternatives, applying similar principles to EVs enables automakers to achieve strong acceleration and range while reducing reliance on expensive components like the geopolitically risky high-capacity batteries, oversized rare-earth motors, and supply-chain challenged chips and power electronics.

By optimizing power delivery through gearing, manufacturers can extract more performance from smaller motors and extend range without adding battery. OEMs who do adopt will see lower production expenses and enhanced vehicle efficiency, creating a clear divide in the EV market between cost-effective, high-performing models and those that remain constrained by the inherent limitations of single-speed drives.

The story of transmissions is one of necessity, innovation, and eventual ubiquity. Historically, they unlocked efficiency, performance, and cost advantages for combustion engines, shaping the trajectory of automotive design. Now, as EVs dominate the future, the same fundamental forces are at play. The industry’s early skepticism toward multi-speed transmissions in EVs mirrors past resistance to technological shifts—but as history has shown, efficiency, cost, performance advantages ultimately drive adoption. With automakers seeking new ways to differentiate on cost, range, and power delivery, the case for multi-speed EV transmissions is only growing stronger.

Just as they once transformed ICE vehicles, transmissions will once again prove inevitable in shaping the next generation of electric mobility.

About Inmotive Inc.

Inmotive is a pioneering developer of ultra-efficient multi-speed powertrains for electric vehicles. The company’s flagship product, the Ingear™ transmission, delivers superior efficiency and performance for a wide range of EV applications. Committed to advancing sustainable mobility, Inmotive partners with leading manufacturers to redefine what’s possible in electric and alternative energy transportation.

Inmotive Licenses To Cutting Edge EV OEM, Together Targeting the World’s Most Efficient Electric Drive Unit (EDU)

Inmotive’s breakthrough technology is unlocking unrivaled efficiency for licensees.

Inmotive’s breakthrough technology is unlocking unrivaled efficiency for licensees.

Toronto, Canada – Jan 8th, 2025

Inmotive, a pioneer in two-speed transmission technology, is proud to announce a licensing agreement with a prominent US-based electric vehicle OEM. This collaboration focuses on integrating Inmotive’s Ingear™ technology for developing the OEM’s next-generation electric drive unit (EDU) system, targeting unparalleled efficiency and performance.

With the global EV and battery markets evolving rapidly, this partnership is a significant step in creating globally competitive EVs. By leveraging Inmotive’s proprietary transmission technology, the project aims to deliver one of the world’s most efficient EDU systems, setting a new standard in electric vehicle powertrain innovation.

“Inmotive is dedicated to providing solutions that enhance EV efficiency and performance,” said Paul Bottero, CEO of Inmotive. “This licensing agreement underscores our shared vision of optimizing electric powertrains to deliver groundbreaking results for groundbreaking vehicles.”

Key areas of collaboration include, extending vehicle range, reducing EDU cost and utilizing EDU capabilities to unlock lower cost battery systems while still meeting vehicle design requirements. In addition to leveraging Ingear capabilities to reduce energy consumption, the teams will be evaluating U.S.-based EDU assembly options. The OEM and Inmotive are targeting 2027 for the start of EDU production.

The collaboration underscores Inmotive’s dedication to delivering transformative technology that not only achieves ambitious efficiency targets but also enhances cost competitiveness, ensuring US EV manufacturers can bring innovative, high-efficiency vehicles made in the US to the US market without compromising on affordability or scalability.

For more information about Inmotive and its innovative Ingear™ technology, please visit www.inmotive.com or contact Scott McBroom, Inmotive VP, Corporate and Business Development

About Inmotive Inc.

Inmotive is a pioneering developer of ultra-efficient multi-speed powertrains for electric vehicles. The company’s flagship product, the Ingear™ transmission, delivers superior efficiency and performance for a wide range of EV applications. Committed to advancing sustainable mobility, Inmotive partners with leading manufacturers to redefine what’s possible in electric and alternative energy transportation.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Inmotive Forges Strategic Partnership Agreement with Bando Chemical Industries

The greement aims to accelerate the adoption of Inmotive’s Ingear in two- and three-wheel applications

The agreement aims to accelerate the adoption of Inmotive’s Ingear in two- and three-wheel applications

TORONTO, Ontario – November 12th, 2024

Inmotive announced today that it is entering a strategic partnership agreement with Bando Chemical Industries, Ltd., a Tier 1 automotive supplier in Japan. Under the agreement, the two companies will collaborate to accelerate the adoption of Inmotive’s Ingear 2-speed transmission in the two- and three-wheel vehicle market.

Bando Chemical Industries is a global supplier of power transmission belts and conveyor belts, with significant experience providing transmission belts for two-wheeled applications, such as motorcycles. Its belt and tensioner expertise complement Inmotive’s ability to deliver a unique and efficient 2-speed transmission design.

“Our partnership with Bando Chemical Industries brings together our shared technological know-how and like-minded drive to create a cleaner future through eco-friendly technologies,” said Paul Bottero, CEO, Inmotive. “We expect to unlock even more potential for our Ingear by leveraging our combined strengths through this cooperation.”

The Ingear – the world’s most efficient 2-speed transmission designed specifically for EVs – features a compact and simple design with a patented geometry that ensures a smooth and quiet ride. Additionally, the Ingear has been strategically designed to improve electric vehicle cost, range and performance. First adapted for EV passenger cars, Inmotive envisions a broader path to market for its innovation, including motorcycles, scooters, ATVs, marine applications and more.

“We believe the Ingear can be used for a wide array of applications, and we look forward to working toward a proof of concept in this new market segment,” continued Bottero.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 31 patents issued and 55 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Bando Chemical Industries, Ltd.

Bando Chemical Industries, Ltd. is a pioneer in the non-tire rubber and plastics industries since its founding in 1906. To meet the ever-changing needs of the times, the company now produces a wide range of products, from power transmission and conveyor belts and systems to precision equipment components, plastic films and sheets, hybrid rubber industrial products and optoelectronic and electronic materials.

It is serious about its corporate social responsibility efforts and considers energy conservation, the environment and effective resource utilization in all phases of its production processes.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Inmotive Ranked #1 in Canada's Companies-to-Watch In Deloitte's Technology Fast 50 Program

“Our vision is simple: enable the production of electric vehicles that don’t break the bank” - Paul Bottero, CEO of Inmotive.

“Our vision is simple: enable the production of electric vehicles that don’t break the bank” - Paul Bottero, CEO of Inmotive.

TORONTO, Ontario – November 8th, 2024

Inmotive has been ranked as the top company in the Companies-to-Watch category in Deloitte's 2024 Technology Fast 50™ program. This award celebrates emerging technology companies in Canada with significant potential based on their impressive revenue growth and innovation.

Inmotive’s flagship innovation, the Ingear™, is a two-speed transmission designed specifically for electric vehicles; it offers the highest efficiency and performance of any two-speed transmission on the market and closely resembles single speeds in costs and ease of integration. Their work addresses some of the biggest challenges in the EV industry, such as improving electric vehicle range, increasing performance and driveability, and making electric vehicles more accessible through lowering total system costs.

The success of Inmotive stems from its talented and diverse team of professionals who bring together deep expertise in mechanical engineering, automotive design, and EV systems. Leaders with extensive experience in automotive technology and a shared passion for simplifying complex engineering challenges founded the company in 2010. The team is in discussions with leading OEMS to non-exclusively license and integrate their technology into a wide variety of vehicle classes.

The Companies-to-Watch award highlights Inmotive's commitment to innovation and reshaping the future of electric mobility. Inmotive is honored to be recognized among a group of Canadian innovators tackling global challenges. With its advanced transmission technology, Inmotive is driving sustainable solutions in the electric vehicle industry, aiming to reshape mobility standards worldwide.

“Our vision is simple: enable the production of electric vehicles that don’t break the bank,” said Paul Bottero, CEO of Inmotive. “This recognition from Deloitte reinforces that what we’re building at Inmotive is impactful—technology that’s not just revolutionary but accessible. We’re thrilled to be named the top company to watch, and this is just the beginning. Our team will continue pushing boundaries and driving the future of efficient, affordable electric mobility.”

The Companies-to-Watch award is presented to Canadian technology companies that have demonstrated strong growth potential over the past three years. To qualify, this year's winners were required to meet revenue criteria, including a minimum of $50,000 in 2021 and $2.5 million in 2023, positioning them as future leaders in the industry.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 31 patents issued and 55 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Deloitte Technology Fast 50 Program

The Deloitte Technology Fast 50 program is Canada’s pre-eminent technology awards program, recognizing business growth, innovation, and entrepreneurship in four distinct categories: Technology Fast 50, Enterprise—Industry Leaders, Clean Technology, and Companies-to-Watch. Now in its 25th year, the program also includes companies in the North American Technology Fast 500 program. Program sponsors for 2024 include RBCx, Osler, EDC, CCI, TMX, Clarity, and Lafond. For more information, visit www.fast50.ca.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Inmotive Enters Second Phase of Joint Development Agreement with Suzuki for Implementation of its Ingear Two-Speed EV Transmission

Expanded program looks to determine cost-effective mass manufacturing methods for the two-speed EV transmission

Initial phase validated viability for wider in-vehicle implementation, highlighted capability of Ingear in EV passenger cars.

TORONTO, Ontario – April 18, 2024

Inmotive announced that it will move into the second phase of the joint development agreement with Suzuki to develop an Ingear™ 2-speed EV transmission for future Suzuki electric vehicles. The development agreement, executed in January of 2023, was designed to determine viability and compatibility of the Ingear EV transmission with future Suzuki electric vehicles.

“Our teams spent the past year working closely to prepare and validate the Ingear for full implementation into a future EV model,” said Paul Bottero, CEO, Inmotive. “The first phase of development was a meaningful step for both sides, with significant collaboration and approaches to problem solving making steady progress, and we look forward to working jointly on the next phase of development.”

The Ingear is the world’s most efficient 2-speed transmission designed specifically for EVs, validated by Inmotive test results. Through its compact and simple design, the Ingear can improve electric vehicle cost, range and efficiency. Additionally, an Ingear can extend EV range by up to 15% and improve acceleration by up to 15%. Its patented geometry ensures a smooth and quiet ride.

In addition to EV passenger cars, the Ingear can be built for use in a wider range of vehicles, including motorcycles, ATVs, and marine applications. Suzuki is currently exploring the potential for these applications beyond passenger cars.

“The unique design and performance advantages really lends to a multitude of uses,” said Bottero.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 31 patents issued and 55 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Suzuki Motor Corporation

Suzuki, which has the company motto “Develop products of superior value by focusing on the customer,” currently offers products in three mobility categories — automobiles, motorcycles, and outboard motors. The company aims to remain indispensable to people by staying closely attuned to lives and providing mobility.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Inmotive Hires New Vice President of Engineering

Expanded program looks to determine cost-effective mass manufacturing methods for the two-speed EV transmission

Dan Boxeth has more than 30 years of automotive experience, specializes in energy and propulsion management

TORONTO, Ontario – March 25th, 2024

Inmotive announced that it has hired Dan Boxeth as its new vice president of Engineering to lead Inmotive’s growing engineering team.

Boxeth previously worked for Ford Motor Company for 31 years, first joining the OEM as a powertrain engineer and most recently serving as chief technical officer on several Ford product programs. His strong history within the industry gives him substantial experience in technical project management and execution, leading cross-functional teams, and launching new vehicles and technologies.

At one point in his career at Ford, he served as the engineering manager of Core Vehicle Energy Management, responsible for developing new requirements, methods, and tools to improve the company’s execution of vehicle energy management initiatives. Additionally, he helped support the creation and implementation of new global processes for fuel economy that balanced customer, regulatory and real-world achievable expectations. He also had a hand in electrical energy management and prioritization. Similarly, in other roles, he led the execution of an all-wheel-drive electric motor and led the development of Ford’s stop-start technology, among other milestones and impactful projects.

“In our pursuit of a vice president of Engineering, we were looking for someone who would bring exceptional technical knowledge, skills and engineering leadership to our team – and Dan has that in spades,” said Paul Bottero, CEO, Inmotive. “With his knowledge of propulsion and clean energy systems, Dan will have a tremendous impact on elevating the role we play in the global electrification revolution.”

Dan also served as a captain in the United States Army Reserve. He graduated with a bachelor’s degree in mechanical engineering from Rose-Hulman Institute of Technology and earned a master’s degree in mechanical engineering from the University of Michigan.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 18 patents issued and 17 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Beyond Batteries: EV Transmission's Impact on Range and Efficiency

Discover how mechanical innovation boosts the range, efficiency, and sustainability of electric vehicles.

Discover how mechanical innovation boosts the range, efficiency, and sustainability of electric vehicles.

Cutaway view of EV motor

The electrifying world of electric vehicle (EV) innovations is driving us toward a sustainable and emissions-free future. Over the past five years, EV adoption has surged, but there's still a long road ahead to meet government-mandated goals for phasing out combustion vehicles. While much attention has been lavished on battery and electronic innovations in the EV sector, mechanical solutions have been overlooked. These innovations might not grab headlines, but they hold the potential to revolutionize EVs in ways that are efficient, practical, and cost-effective.

EVs have come a long way, but challenges remain. The compromises between performance and cost have been a persistent hurdle. Picture this: EVs designed for performance excel in one aspect of the operating torque-speed spectrum but falter in others, limiting their efficiency and overall range. The key challenge lies in improving the efficiency of EV powertrains across a broad range of operating conditions without compromising performance.

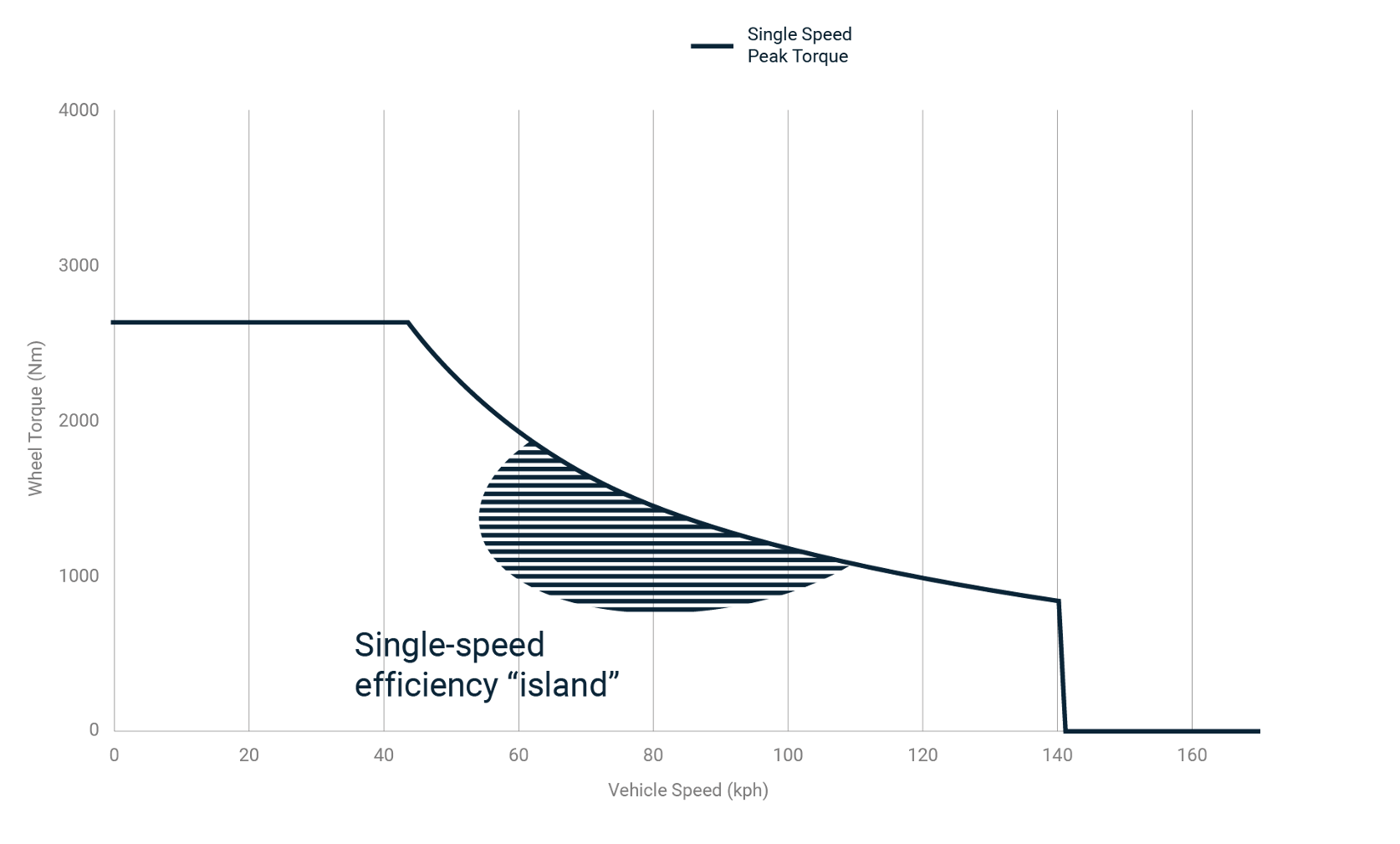

Single-speed EV transmission efficiency island

Current single-speed transmissions in EVs struggle to strike the right balance. For instance, climbing steep hills or hauling heavy loads can push the limits of efficiency, draining batteries faster than expected and impacting range. While the promise of better batteries and power electronics looms on the horizon, a new kind of EV transmission offers immediate performance improvements without waiting for breakthroughs in these technologies.

Ingear Transmission

Cutaway view of the Ingear two-speed transmission for EVs

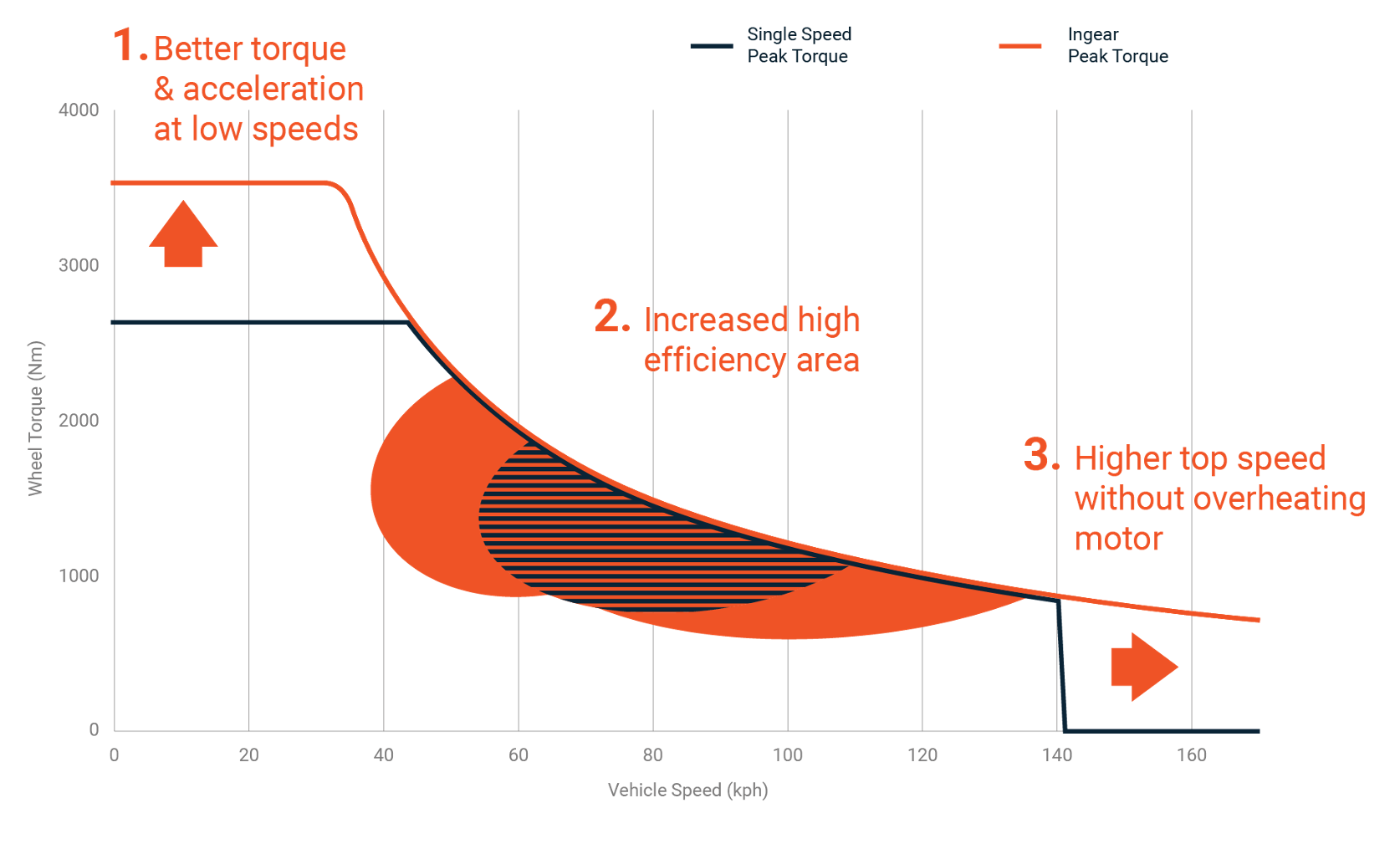

Ingear is a groundbreaking two-speed EV transmission designed by Inmotive. This mechanical marvel shifts with precision and is the world's most efficient transmission, purpose-built for EVs. Unlike conventional single-speed transmissions, Ingear optimizes performance across the entire torque-speed range, enhancing acceleration, top speed, and, most importantly, efficiency.

Ingear's uniqueness lies in its geometry-based shifting, a departure from the conventional gear-shifting mechanisms. It enables electric motors to operate at peak efficiency, translating to remarkable benefits. The data tells an impressive story: Ingear can extend an EV's range by an average of 9%. This reduction in energy consumption means that EVs can travel farther with the same battery capacity, a game-changer for long journeys.

The increased efficiency of a two-speed EV transmission

Ingear's benefits extend to both city and highway driving. It can boost acceleration and top-speed performance by up to 15%, all while maintaining the efficiency of a single-speed transmission.

What sets Ingear apart is its purpose-built design for EVs, eliminating the need to adapt or modify transmissions from combustion vehicles. It's a cost-effective solution, with a low part count and the use of common materials. The savings ripple throughout the powertrain, yielding up to $1500 in net cost savings in other components, such as reduced motor or battery sizes. Efficiency testing conducted by a global tier 1 auto supplier and pricing analysis by RITE Consulting validates Ingear's potential. These findings represent real-world production costs at automotive volumes, making Ingear an attractive proposition for manufacturers seeking to optimize cost and performance.

The 9% efficiency improvement isn't just about savings; it's about reducing the environmental footprint. Less manufacturing, reduced electricity consumption per vehicle, and a higher adoption rate of EVs can lead to substantial carbon savings. Furthermore, this efficiency translates into direct savings for EV owners, putting money back into their pockets.

Woman charging EV

Inmotive's Ingear is a testament to the power of mechanical innovation in the EV industry. While batteries and electronics grab headlines, Ingear quietly paves the way for efficient, sustainable, and high-performance electric mobility. It's time to expand our horizons, recognizing that innovation in EVs is multifaceted.

As we look to the future, Inmotive envisions a world where mechanical innovations play a pivotal role in enhancing EVs. Our mission is to make EVs accessible, efficient, and affordable for all. Ingear represents a significant step toward this vision, and we're excited to continue pushing the boundaries of what's possible in the electric vehicle landscape.

Join us on this journey to unlock the full potential of EVs, proving that innovation is not limited to batteries and electronics. It's about reimagining the mechanics that drive us forward.

Inmotive Extends Partnership with Nissin, Examines Mass Manufacturing Options for the Ingear

Expanded program looks to determine cost-effective mass manufacturing methods for the two-speed EV transmission

Expanded program looks to determine cost-effective mass manufacturing methods for the two-speed EV transmission

TORONTO, Ontario – November 29, 2023

Inmotive announced today that it is extending its collaboration with Nissin Manufacturing Co., (Kyoto, Japan), through a non-exclusive agreement to investigate cost-efficient mass manufacturing methods. Specifically, the companies will jointly examine ways to mass produce sprocket segments, which are a critical component of Inmotive’s Ingear™ two-speed electric vehicle transmission, to optimize costs for potential customers.

Nissin, founded in 1946, produces a wide range of precision parts for various industries, including automotive and transportation. Inmotive initially entered into a strategic alliance with Nissin in September 2022 to further promote the Ingear in Japan, expanding the company’s market opportunities and providing another option for manufacturing in Asia.

“This new agreement is a natural progression of the strong collaboration we’ve established with Nissin to this point, and we look forward to uncovering cost efficiencies that will positively impact taking Ingear production to the next level,” said Paul Bottero, CEO, Inmotive. “The outcome of this project will provide OEM customers with superior, lower cost options while increasing adoption of the Ingear.”

Nissin will utilize its extensive manufacturing expertise and supplier network to lead the charge for developing the cost-effective mass production method of the Ingear, while Inmotive will provide engineering and validation support to ensure the identified methods produce parts that meet functional and durability requirements.

“We are continuing to look for products that promote sustainability and position our business well into the future,” said Takashi Nishikohri, Chairman, Nissin Manufacturing Co. “We have high hopes that this partnership will lead to the creation of outstanding products with the combination of Inmotive’s development expertise and our manufacturing capabilities.”

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear reduces EV cost and weight, while extending range and increasing torque, acceleration, gradeability and top speed. It is protected with 23 patents issued and 46 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Nissin Manufacturing Co.

Nissin is a Japanese based manufacturer focused on mass-produced parts for automobiles, motorcycles and more, as well as production systems including ultra-precision honing machines and IoT systems. Its integrated processing capabilities from development to global production is highly regarded by many OEMs. Nissin is headquartered in Kyoto, Japan, with factories in China, Thailand, Indonesia, Vietnam and Mexico. More information is available at www.nissin-mfg.co.jp.

Media Contact

Brittney Popa

MBE Group (on behalf of Inmotive)

(231) 675-1692

bpopa@mbe.group

Inmotive Receives Strategic Investment from Suzuki

Strategic equity investment follows joint development agreement between the two companies

Strategic equity investment follows joint development agreement between the two companies

TORONTO, Ontario – October 23, 2023

Inmotive announced today that Suzuki is investing in its company, further supporting its Ingear™ 2-speed EV transmission development. The investment is via the Suzuki Global Ventures (SGV) fund, which was established in October 2022 and aims to accelerate the co-creation of activities between start-ups and Suzuki in addition to creating new businesses and business models.

This investment follows the signing of a joint development agreement (JDA) between the two companies in January 2023. The JDA specifies how Inmotive’s Ingear 2-speed EV transmission is developed to extend range and reduce cost for future Suzuki electric vehicles. To date, the JDA with Suzuki is progressing according to plan and all deliverables have been met.

“Having Suzuki as a partner has been a tremendous opportunity for the commercialization of the Ingear and we are excited to have the company extend its support of our eco-friendly technology with their recent investment,” said Paul Bottero, CEO, Inmotive. “It is through collaborations and investments like this that we will be able to bring our vision of accelerating the global evolution to affordable zero- emission mobility to life.”

“This strategic investment further enhances our close working relationship with Inmotive and underscores our commitment to making investments that address key issues globally as well as our dedication to the Ingear technology,” said Toshihiro Suzuki, President, Suzuki Motor Corporation. “We are taking great strides toward a successful deployment of the Ingear on Suzuki vehicles and look forward to continuing down that path.”

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear reduces EV cost and weight, while extending range and increasing torque, acceleration, gradeability and top speed. It is protected with 23 patents issued and 46 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Suzuki Motor Corporation

Suzuki, which has the company motto “Develop products of superior value by focusing on the customer,” currently offers products in three mobility categories — automobiles, motorcycles, and outboard motors. The company aims to remain indispensable to people by staying closely attuned to lives and providing mobility.

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(231) 675-1692

bpopa@mbe.group

Inmotive’s Ingear Confirmed as World’s Most Efficient Two-Speed Transmission for EVs by Major Global OEM

Efficiency test results show over 99% peak efficiency

Efficiency test results show over 99% peak efficiency

TORONTO, Ontario – July 13, 2023 – Inmotive has received confirmation from a major global OEM that its Ingear™ two-speed EV transmission is the world’s most efficient two-speed transmission for electric vehicles – a claim Inmotive has made since the launch of the EV technology based on its own in-house testing.

Validation was conducted via an efficiency test bench at the OEM’s facilities using a full transmission assembly with torque cells mounted at the input (motor) and output (CV shaft), which showed that the Ingear achieves over 99% peak efficiency. Simulations show a two-speed Ingear increases EV range by 7-13% compared to the range of a single speed.

Beyond the major OEM, in May 2021 Inmotive reported a Tier One automotive supplier had confirmed the results, as has another Tier One transmission supplier since.

“Having a major, global OEM confirm that our Ingear is in fact the world’s most efficient two-speed transmission for electric vehicles validates our design and highlights the value we’re ready to deliver to the market,” said Paul Bottero, CEO, Inmotive. “This is more proof that the Ingear is delivering on our claims of high efficiency, dramatically lowering the system cost of electric powertrains. We’re thrilled to offer OEMs and suppliers a low-cost solution that enables and accelerates the global shift to lower cost, mass market EVs.”

Through its compact and simple design created specifically for EVs, the Ingear can deliver lower system costs to OEMs and improve acceleration by up to 15%. Its patented geometry also ensures a smooth, quiet ride and improves top-speed, towing capability and gradeability.

Latest project milestones and development status

Beyond efficiency validation, Inmotive has successfully completed the initial robustness and durability testing of the Ingear transmission. To do so, it completed cyclic testing involving over 100,000 shifts with results showing each shift transmitted 80Nm of motor torque in LO gear into 155Nm of torque in HI gear through every upshift. The Ingear design enables unparalleled shift smoothness without loss of torque.

By the end of Q1 2024, Inmotive will have a prototype of a higher torque unit for 400-500Nm motors, which is double the Ingear’s current output.

To date, Inmotive has completed four vehicle conversion evaluation trials. Combining that experience with the proof of imperceptible shifts and high efficiency, initial durability, and a path to wider applications, the Ingear is ready to be integrated into EV programs now.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 23 patents issued and 46 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

Ingear Image Download: https://bit.ly/3PJF2Gc

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(231) 675-1692

bpopa@mbe.group

Inmotive Demonstrates Ingear Robustness, Achieves Key Project Milestone

Ingear has successfully completed the initial robustness and durability testing of the Ingear transmission

TORONTO, Canada – May 29, 2023

Inmotive, the inventor of the Ingear™ two-speed electric vehicle (EV) transmission, is proud to announce a significant milestone on its journey toward commercialization: the company has successfully completed the initial robustness and durability testing of the Ingear transmission.

By completing cyclic testing involving over 100,000 shifts, the Ingear transmission was able to achieve this key project breakthrough. Each shift transmitted 80Nm of motor torque in LO gear into 155Nm of torque in HI gear through every upshift. Unlike any other EV transmission on the market, Ingear delivers continuous torque during gear changes, providing unparalleled shift smoothness without loss of torque. These torque levels represent typical acceleration for a mass market passenger vehicle.

The testing process utilized a full transmission assembly on a loaded test bench with a 150kW motor and EV battery emulator setup. Inmotive engineers designed and constructed this testing platform at its facility in Toronto, Canada.

These initial test results demonstrate a significant number of loading cycles on major components, fulfilling a crucial robustness milestone and showcasing important progress along the company’s planned path to market commercialization. With these developments, Inmotive continues to have confidence that the Ingear transmission is well positioned for widespread adoption and, by improving vehicle affordability, can help accelerate adoption of EVs globally.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 23 patents issued and 46 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(231) 675-1692

bpopa@mbe.group

Inmotive Enters Joint Development Agreement with Suzuki for Implementation of its Ingear Two-Speed EV Transmission

An Ingear to be developed for a future Suzuki electric vehicle

An Ingear to be developed for a future Suzuki electric vehicle

TORONTO, Canada – January 10, 2023

Inmotive has signed a joint development agreement with Suzuki to develop an Ingear™ 2-speed EV transmission for a future Suzuki electric vehicle.

“This partnership with Suzuki exemplifies the value that the Ingear two-speed transmission can bring to electric vehicles, including cost, range, performance and efficiency improvements,” said Paul Bottero, CEO, Inmotive. “Jointly developing our technology for a future Suzuki vehicle is a big step toward commercialization and realizing Inmotive’s vision of accelerating the global evolution to affordable zero-emission mobility.”

The Ingear is the world’s most efficient 2-speed transmission designed specifically for EVs. Through its compact and simple design, the Ingear can improve electric vehicle cost, range and efficiency. An Ingear can extend EV range by up to 15% and improve acceleration by up to 15%. Its patented geometry ensures a smooth and quiet ride.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 18 patents issued and 17 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe and China. More information is available at www.inmotive.com.

About Suzuki Motor Corporation

Suzuki, which has the company motto “Develop products of superior value by focusing on the customer,” currently offers products in three mobility categories — automobiles, motorcycles, and outboard motors. The company aims to remain indispensable to people by staying closely attuned to lives and providing mobility.

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(231) 675-1692

bpopa@mbe.group

Inmotive and Nissin Establish Agreement to Expand Ingear™ EV Transmission Market Reach in Japan

Agreement Enables Ingear™ Promotion in Japan through Nissin’s global network; meets the needs of a rapidly growing EV market in Japan

Agreement Enables Ingear™ Promotion in Japan through Nissin’s global network; meets the needs of a rapidly growing EV market in Japan

TORONTO, Canada – September 9, 2022

Inmotive, the inventor of the Ingear™ two-speed electric vehicle transmission, today announced it has entered into a strategic alliance with Nissin Manufacturing Co., (Kyoto, Japan), to further promote the Ingear in Japan.

The Ingear is the world's most efficient 2-speed transmission, designed specifically for electric vehicles. “Nissin is widely known as an expert manufacturer of precision products and this alliance will help increase awareness of the Ingear as a viable powertrain option for EVs within Asia that can help meet the needs of a rapidly growing EV market within Japan,” said Paul Bottero, CEO, Inmotive.

While Inmotive is currently in development with Japanese OEMs, the promotion alliance with Nissin, increases the market opportunity, while also providing another option for manufacturing in Japan. Nissin, founded in 1946, produces a wide range of precision parts for various industries, including automotive and transportation. While the Ingear project will start in Japan, there is opportunity for expansion to Nissin’s global network.

Inmotive has been developing the Ingear transmission with the intent of improving cost, efficiency, and range for EVs. The unique two-speed design delivers extensive cost savings and extends EV range by up to 15%, and is scalable in design to enable use on a wide range of vehicle applications.

It is currently in development phases with multiple automakers and is expected to be launched in vehicles by 2026.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 18 patents issued and 17 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in Europe, Japan and China. More information is available at www.inmotive.com.

Media Contact

Frank Buscemi

MBE Group on behalf of Inmotive

(248) 856-8636

fbuscemi@mbe.group

Inmotive Addresses EV “Torque Hole” Issues with Unique Transmission Geometry

Ingear two-speed electric vehicle transmission achieves imperceptible shifts at 100 Nm. Passenger experience is as smooth as a single-speed gearbox under normal driving, unlike other multi-speed transmissions that could be applied to EVs

Ingear two-speed electric vehicle transmission achieves imperceptible shifts at 100 Nm

Passenger experience is as smooth as a single-speed gearbox under normal driving, unlike other multi-speed transmissions that could be applied to EVs

TORONTO, Canada – October 14, 2021

Inmotive, the makers of the Ingear two-speed transmission for electric vehicles (EVs), today announced that its latest vehicle prototype has achieved imperceptible shifts at 100 Nm, making great strides in eliminating “torque hole” issues that can be found in traditional transmissions.

“This is a significant milestone and has been a major priority for Inmotive, to ensure that there is no loss of torque during shifting,” said Paul Bottero, CEO of Inmotive. “Our intent from the beginning was to create a multi-speed EV transmission that shifts so smoothly, it compares to a single-speed transmission and gives drivers the torque feel they’ve come to expect from EVs.”

Inmotive is currently working to bring the Ingear to market. Invented and designed for the next generation of electric vehicles, the Ingear features a simple and durable design that enables a more efficient powertrain, with extended range, at lower cost.

The company has worked to solve the “torque hole” problem through a combination of improved geometry, better tensioner control and careful motor commands. Currently, the Ingear’s geometry can handle full load throughout the shift, with the system transmitting 130 Nm of peak torque throughout the shift dynamically.

“This is something that has plagued the transportation industry for a long time,” Bottero said. “With our immense improvements, EVs can now have the benefits of a multi-speed transmission without losing efficiency while driving, spending energy to shift, or abrupt disconnects or disruptions to the smooth acceleration.”

Traditionally, the “torque hole” issues have been alleviated with expensive, complicated clutch systems that consume a lot of energy during a shift and are not efficient even when not shifting.

With the Ingear, EV drivers and passengers may not notice that a transmission is in their vehicle, so they get all the benefits and no discomfort during normal driving.

Currently, Inmotive has confirmed the results with independent test drivers and OEM development partners.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 16 patents issued and 17 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in India and China. More information is available at www.inmotive.com.

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(248) 554-3507

bpopa@mbe.group

Inmotive’s Ingear Demonstrates Over 99% Peak Efficiency

Measurements Validated by Tier One supplier

Measurements Validated by Tier One supplier

TORONTO, Canada – May 26, 2021

Inmotive, the inventor of the Ingear™ two-speed electric vehicle transmission, today announced it has received the results of a recently conducted, third-party efficiency test further validating that the Ingear is the world’s most efficient two-speed EV transmission.

A Tier One automotive supplier conducted the efficiency testing at its facilities. After measuring both gears over a wide range of torque and speeds, test results show that the Ingear achieved more than 99% peak efficiency in low gear and nearly 98% while in high gear. The test was conducted on a full transmission, including a primary reduction gear, oil lubrication and all necessary bearings and seals.

Unlike the helical gear that it replaces, the Ingear has a large efficiency sweet spot, which includes all of the gear/torque/speed combinations used in a drive cycle such as WLTP. These third-party results validate Inmotive’s own efficiency testing, which underpinned Inmotive’s claims made when launching the Ingear in September 2020. They also further substantiate Inmotive’s claim that a low cost Ingear will extend a typical EV’s range by more than 7% (WLTP).

“The silent chain is the most efficient type of chain or belt available and can incur less friction than even the most efficient gears,” said Anthony Wong, CTO of Inmotive. “And without the axial forces generated by the ubiquitous helical gears, we're able to use ball bearings instead of tapered roller bearings, saving substantial losses. Our clutchless shifting methodology is hyper-efficient as well, using only 740 Joules per shift cycle - the equivalent of six seconds of headlight usage.”

“The test results of the Ingear two-speed transmission confirms that electric vehicles can have greater range than originally thought,” said Paul Bottero, CEO of Inmotive. “EV designers can incorporate the low-cost Ingear to extend range and lower vehicle cost, while improving acceleration, towing capability and gradeability.”

Full test results are available to qualified customers and industry partners under NDA.

About Inmotive Inc.

Inmotive is the Canadian based inventor of the Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends electric vehicle range at very low additional cost and weight, while providing continuous torque during smooth shifts. Its highly reliable design also increases torque, acceleration, gradeability and top speed and is protected with 16 patents issued and 17 patents pending. Inmotive is headquartered in Toronto, Canada, with offices in India and China. More information is available at www.inmotive.com.

Media Contact

Brittney Popa

MBE Group on behalf of Inmotive

(248) 554-3507

bpopa@mbe.group

Inmotive’s CTO Featured in SAE Webinar Highlighting Electric Vehicle Transmission Development Priorities